Experimentation with an plaster material that represents an alternative to cement screed and concrete topping

NEWS

April 2023: Film Gypsum Concrete

Publication of the film Gypsum Concrete, which retraces in images the development of the eponymous research carried out by ciguë architectes.

February 2022 : Gypsum Concrete in Télérama

Télérama highlights the study conducted by ciguë architects in an article dedicated to the exhibition Béton de Plâtre, presented until February 6, 2022 at the Pavillon de l'Arsenal.

Publication of the film Gypsum Concrete, which retraces in images the development of the eponymous research carried out by ciguë architectes.

February 2022 : Gypsum Concrete in Télérama

Télérama highlights the study conducted by ciguë architects in an article dedicated to the exhibition Béton de Plâtre, presented until February 6, 2022 at the Pavillon de l'Arsenal.

January 2022 : Exhibition Gypsum Concrete

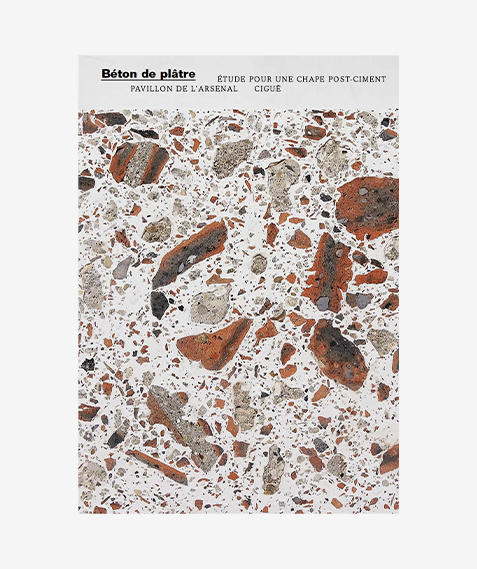

Study for a post-concrete slab

Presented from January 20 to February 6, 2022

Once very widely used in Parisian constructions, gypsum plaster (which had turned the French capital completely white in the seventeenth century) has declined substantially in use due to the advent of modern forms of concrete and building materials. As we are now re-examining our production methods in order to find more sustainable and less carbon-intensive solutions, ciguë’s architects have investigated the contemporary potential of this endemic material.

Their research, conducted with the support of the FAIRE project accelerator, proposes investigating the potential use of gypsum plaster for slab production, an alternative to Portland cement, which currently accounts for almost 30.3% of the greenhouse gas emissions in France’s building industry. Their study also intends to prove the merits of gypsum plaster as a binder that’s capable of replacing natural aggregates (sand and gravel, currently facing depleted reserves) by construction rubble (crushed bricks, tiles, or Portland cement).

The Gypsum Concrete exhibition (and its companion publication) presents the record of two years of research exploring possible mixes that could be used to produce post-cement slabs. Through samples, test results, prototypes, and films, this event charts the laboratory studies and experimentations conducted in real-world conditions. It also forms part of a longer-term research project that will result in the construction of a mixed-used building (workshop and housing) in Montreuil, followed by the in-situ analysis of the longevity of this new material.

The research was supported by the Plâtres Vieujot gypsum plaster transformation factory (located in Soisy-sous-Montmorency in the Val d’Oise department) and by researchers from the Granulates & Materials Processing laboratory (GPEM) of the Materials and Structures (MAST) department at Université Gustave Eiffel, as well as the engineering consultancy Le Sommer. Findings have confirmed the base assumptions. Gypsum plaster concrete made from mixed reclaimed bricks and tiles exhibits very high compressive strength, puncture strength, and abrasion resistance. Mixes including reclaimed Portland concrete could be put to use for their mass and soundproofing properties. And, whatever the formulation ultimately used, gypsum plaster slabs make much better use of natural resources while substantially lowering greenhouse gas emissions compared to conventional concrete slabs.

Concerned with the exploration of other production methods at the nexus between building trades and know-how, ciguë’s architects aren’t aiming to promote an “all-plaster” approach. but rather, their aim is to inform a more comprehensive examination in the face of the excesses and constraints -that are the hallmarks of our era.

The Gypsum Concrete project reflects “our ability, as architects, to adopt a new perspective on available resources, to redefine our relationship to materials, and to continue calling into question the systemic reflexes at work in contemporary build practices.

Standing at the crossroads between architecture, design, and installation, ciguë reactivates archetypes to produce contemporary environments. Their projects are characterized by experimentation, stripped-bare esthetics, and radical collage.

Home to a team of twenty in Montreuil, their workshop is an arena where new spaces and materials are developed. By removing the hierarchy between different scales and dissolving the boundaries between various areas of expertise, ciguë reconciles the way we live in the world with the way we build it.

The Gypsum Concrete exhibition (and its companion publication) presents the record of two years of research exploring possible mixes that could be used to produce post-cement slabs. Through samples, test results, prototypes, and films, this event charts the laboratory studies and experimentations conducted in real-world conditions. It also forms part of a longer-term research project that will result in the construction of a mixed-used building (workshop and housing) in Montreuil, followed by the in-situ analysis of the longevity of this new material.

The research was supported by the Plâtres Vieujot gypsum plaster transformation factory (located in Soisy-sous-Montmorency in the Val d’Oise department) and by researchers from the Granulates & Materials Processing laboratory (GPEM) of the Materials and Structures (MAST) department at Université Gustave Eiffel, as well as the engineering consultancy Le Sommer. Findings have confirmed the base assumptions. Gypsum plaster concrete made from mixed reclaimed bricks and tiles exhibits very high compressive strength, puncture strength, and abrasion resistance. Mixes including reclaimed Portland concrete could be put to use for their mass and soundproofing properties. And, whatever the formulation ultimately used, gypsum plaster slabs make much better use of natural resources while substantially lowering greenhouse gas emissions compared to conventional concrete slabs.

Concerned with the exploration of other production methods at the nexus between building trades and know-how, ciguë’s architects aren’t aiming to promote an “all-plaster” approach. but rather, their aim is to inform a more comprehensive examination in the face of the excesses and constraints -that are the hallmarks of our era.

The Gypsum Concrete project reflects “our ability, as architects, to adopt a new perspective on available resources, to redefine our relationship to materials, and to continue calling into question the systemic reflexes at work in contemporary build practices.

Standing at the crossroads between architecture, design, and installation, ciguë reactivates archetypes to produce contemporary environments. Their projects are characterized by experimentation, stripped-bare esthetics, and radical collage.

Home to a team of twenty in Montreuil, their workshop is an arena where new spaces and materials are developed. By removing the hierarchy between different scales and dissolving the boundaries between various areas of expertise, ciguë reconciles the way we live in the world with the way we build it.

Exhibition from January 20 to February 6, 2022

Publication on sale at the Pavillon de l'Arsenal bookstore and online

Research conducted by ciguë architects

GYPSUM CONCRETE

Study for a post-concrete slab, january 2022

BÉTON DE PLÂTRE

Awarded project FAIRE 2019

Published by Pavillon de l'Arsenal, January 2022

Graphic design : Syndicat

13 € / 17,5 x 25 cm / 59 pages.

Book in French only.

PROJECT PARTICIPANTS

ciguë, Camille Bénard, Julien Franc Wahlgreen, Guillem Renard et Alphonse Sarthout

Loïc Dollet and Charlie Roseau are specialists of artisanal plasterwork. They create their very own gypsum plaster, manufactured using heritage production techniques. Dollet and Roseau are both instructors and involve vocational training in their projects. They help us explore on-site material recycling using a traditional plaster kiln on an artisanal scale.

Plâtres Vieujot

Marc Potin is an engineer and plaster manufacturer based in Soisy-sous-Montmorency. He contributes his technical expertise in developing new floor plaster formulations right up to application.

Study for a post-concrete slab, january 2022

BÉTON DE PLÂTRE

Awarded project FAIRE 2019

Published by Pavillon de l'Arsenal, January 2022

Graphic design : Syndicat

13 € / 17,5 x 25 cm / 59 pages.

Book in French only.

PROJECT PARTICIPANTS

ciguë, Camille Bénard, Julien Franc Wahlgreen, Guillem Renard et Alphonse Sarthout

At the crossroads of architecture, design and installation, ciguë reactivates archetypes to produce contemporary worlds.

Its projects are crossed by experimentation, the nudity of the devices and the radicality of collage.

Bringing together a team of 20 people in Montreuil, the workshop is the theater of elaborations of places and materials. By de-hierarchizing the scales and by decompartmentalizing the know-how, ciguë reconciles our way of living the world and of building it.

Le Sommer Environnement

Le Sommier Environnement is an environmental consultancy supporting us in developing a life cycle assessment methodology that takes into account the reuse of rubble on site as well as the use of gypsum plaster, which is a local material with a much lower carbon footprint than cement. They will also evaluate how relevant the development of a dedicated industry in the Île-de-France region would be.

Université Gustave Eiffel

Erwan Hamard and Bogdan Cazacliu are researchers at the GPEM laboratory, specialized in aggregates and processes of materials development. They are experts in the recycling of concrete rubble applied to construction and soil. They support us in developing our experimental protocol and for sample characterization in the lab, prior to potentially standardizing the material.

Pierres de MontreuilIts projects are crossed by experimentation, the nudity of the devices and the radicality of collage.

Bringing together a team of 20 people in Montreuil, the workshop is the theater of elaborations of places and materials. By de-hierarchizing the scales and by decompartmentalizing the know-how, ciguë reconciles our way of living the world and of building it.

Le Sommer Environnement

Le Sommier Environnement is an environmental consultancy supporting us in developing a life cycle assessment methodology that takes into account the reuse of rubble on site as well as the use of gypsum plaster, which is a local material with a much lower carbon footprint than cement. They will also evaluate how relevant the development of a dedicated industry in the Île-de-France region would be.

Université Gustave Eiffel

Erwan Hamard and Bogdan Cazacliu are researchers at the GPEM laboratory, specialized in aggregates and processes of materials development. They are experts in the recycling of concrete rubble applied to construction and soil. They support us in developing our experimental protocol and for sample characterization in the lab, prior to potentially standardizing the material.

Loïc Dollet and Charlie Roseau are specialists of artisanal plasterwork. They create their very own gypsum plaster, manufactured using heritage production techniques. Dollet and Roseau are both instructors and involve vocational training in their projects. They help us explore on-site material recycling using a traditional plaster kiln on an artisanal scale.

Plâtres Vieujot

Marc Potin is an engineer and plaster manufacturer based in Soisy-sous-Montmorency. He contributes his technical expertise in developing new floor plaster formulations right up to application.